One Hull Of A Story: Priestman Oil Engine

|

An article titled as the "Priestman Oil Engine" may not be the most exciting sounding piece you've ever read, but stick with it. As the story of William Dent Priestman, and the invention of his "oil" based internal combustion engine was a major break-through in engineering during the late 1800s. (Yeah, I'm going to have to embellish this one, with moments of tension and at least one explosion.)

William... Billy... Bill Priestman was a gallant, spirited and devout young Quaker. He grabbed life with both hands as he set-out on the adventure of a life-time, by buying the Holderness Foundry in Hull, with money from daddy. Never knowing that his audacious and devil-may-care decision to forge an engineering empire would one day see his name etched in the oily engine block of history. |

Priestman founded the company in 1870 and was soon joined by his brother Samuel, forming Priestman Brothers Ltd. They manufactured industrial machinery, specializing in steam powered dredgers, cranes and diggers. The internal combustion engine had been around since 1860, when Belgian Jean J. Lenoir first mass produced a small engine that simply replaced ignited gas for the steam. By the 1870s, Priestman had gained a licence to design and manufacture engines. The existing designs were considered dangerous, due to the volatile nature of the highly combustible liquids and gases they ran on. High insurances, made their use costly.

|

Priestman developed an engine that ran on a more viscous lamp oil, which was therefore safer to run than the petrol or gas driven engines of the period. As the advert above claims, the safer Priestman engines reduced the insurance costs of running it on site. This was the first internal combustion engine to work successfully on a heavier fuel than petrol. The engine was manufactured by the company from 1888 through to 1904, with around a 1000 engines being produced and shipped all over the world. Priestman Brothers created and variation of engine designs, which included a portable version, and ones which could power electrical lighting systems. The engine was first unveiled in 1893, and patented in 1894. That same year, William and Samuel Priestman were given the prestigious John Scott Legacy Medal for their engine design. An award that was presented to any inventor that, improved the "comfort, welfare, and happiness of human kind".

Experts in these matters claim that there are 3 still operational engines around the world, as far afield as New Zealand. One engine has been preserved as a stationary exhibit at the Streetlife Museum of Transport, in Hull. The engine design was recognised by the Engineering Heritage Hallmark Scheme awarded by the Institution of Mechanical Engineers in 2000 for its significance in British engineering history. |

In 1893 the Priestman Brothers displayed their new engine at an exhibition, that was covered by Engineering Magazine, in their June issue of that year. The magazine explains the unique and innovative self-starter design of the engine, in fine detail. The full text of the article is below, for anyone engineering minded, or geeky enough to work through the text and understand what it actually all means. (Related diagrams can be found in the slide show below.)

|

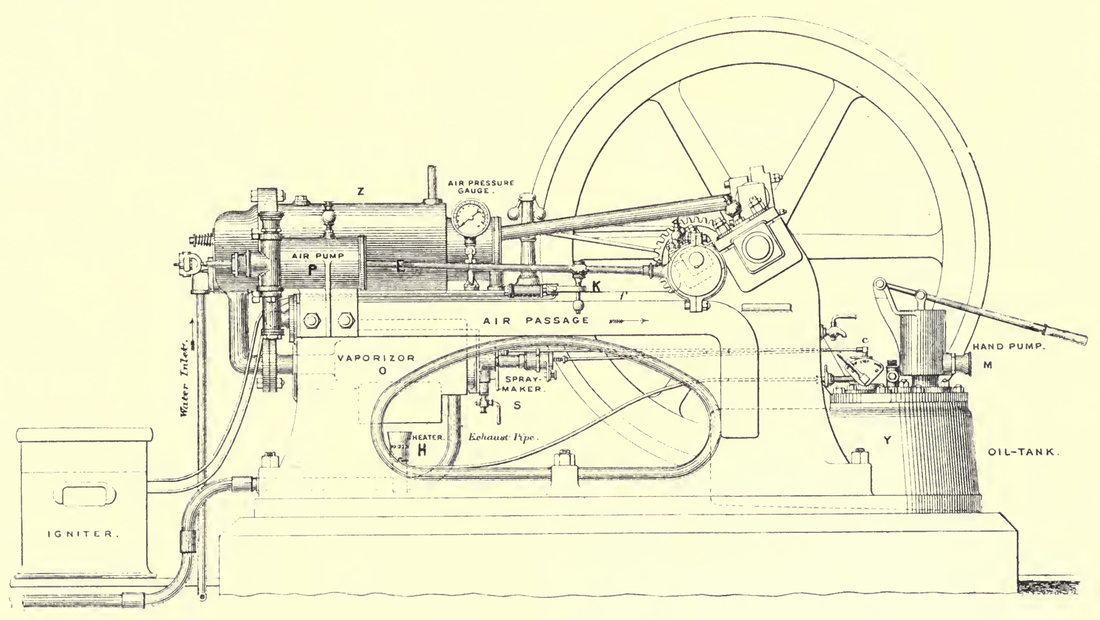

Evidence of the growing size and popularity of the oil engine is found in the fact that it has been found necessary to devise a self-starter for it. During the last three or four years there have been a succession of self-starters for gas engines, but this is the first that has appeared for oil engines. It is shown by Messrs. Priestman Brothers, Limited, Hull. This firm has, as usual, a large and handsomely displayed stand, which bears an appearance of actuality and genuine trade, which is not always associated with oil engines. As our readers will remember, t the Priestman engine has a hand pump, by which a slight air pressure can be brought to bear on the store of oil to make it rise into the spray nozzle. This pump is now utilized to gain a store of air of some twenty pounds pressure. When the vaporiser is heated, and the engine set ready to start, the spray is first turned on, and soon afterwards the compressed air.

|

This carries the charge forward, first filling the vaporiser, and then opening the valve between it and the cylinder, and flowing into that. Here the electric igniter is in full action, and consequently an explosion follows, starting the engine, which, on the next cycle, takes in its regular charge and gets away in the usual manner.

An engraving of this arrangement, as applied to a double-cylinder engine, will be found on page 868, the oil reservoir being utilized as the air vessel. In starting the engine the plugs K, K1 are taken out to ascertain that they are clean, the flywheel is turned until the crank has just passed the centre in the direction of rotation, and the valve E is screwed down perfectly tight. The vaporiser D is then warmed in the usual way, but a little hotter than is necessary when not using the self-starter. By means of the air pump F air is pumped into the oil tank I to a pressure of about 25 lb.; when this is done the engine is ready for starting. A piece of tubing C is put between the forks H to make contact, and while the finger J makes contact in the other forks H1. The electric contacts in both cylinders are then in action. The handle L of the six way cock G is now turned on to "start," and after a minute or less, the cock A is opened with the lever B; this allows the compressed charge in the oil tank I to pass through the vaporiser D and find its way into the cylinders R, ft1, where the sparks are waiting to receive it; the explosion then takes place, and the engine starts. Immediately it starts the cock A is closed. As the finger goes round it will knock out the tube in the other forks. Immediately the engine is started the contact forks H, H' cause the electric current to be adjusted in the usual way.

An engraving of this arrangement, as applied to a double-cylinder engine, will be found on page 868, the oil reservoir being utilized as the air vessel. In starting the engine the plugs K, K1 are taken out to ascertain that they are clean, the flywheel is turned until the crank has just passed the centre in the direction of rotation, and the valve E is screwed down perfectly tight. The vaporiser D is then warmed in the usual way, but a little hotter than is necessary when not using the self-starter. By means of the air pump F air is pumped into the oil tank I to a pressure of about 25 lb.; when this is done the engine is ready for starting. A piece of tubing C is put between the forks H to make contact, and while the finger J makes contact in the other forks H1. The electric contacts in both cylinders are then in action. The handle L of the six way cock G is now turned on to "start," and after a minute or less, the cock A is opened with the lever B; this allows the compressed charge in the oil tank I to pass through the vaporiser D and find its way into the cylinders R, ft1, where the sparks are waiting to receive it; the explosion then takes place, and the engine starts. Immediately it starts the cock A is closed. As the finger goes round it will knock out the tube in the other forks. Immediately the engine is started the contact forks H, H' cause the electric current to be adjusted in the usual way.

|

Join the One Hull Of A City facebook group, and spread the word!

|

One Hull Of A Story: Venn You Are From Hull - One of Hull's famous sons, and inventor of the diagram named after him, John Venn. A fun look at the Venn diagram, Hull style.

|

One Hull Of A Trip: Time-Lapse Train Journeys - You don't have to be from Hull to appreciate this. Two brilliant and unusual time-lapse railway journeys. That should be played together.

|